I had obtained the wheel cylinder before even tearing into the assembly, knowing that was the problem and hoping that nothing else would be needed, save for a couple of cans of brake cleaner. What I ended up with was five lug nuts that had been impacted on so tightly that it took an hour and a full can of penetrating oil to remove, an additional hour of beating and heating to get the drum to release, a handful of springs rusted almost to the point of being unrecognizable that were covered in a thick goop of DOT3 fluid and road grime, a completely missing emergency brake assembly, two BENT cylinder pins, and something that didn't look quite right that I couldn't quite put my finger on.

A somewhat leisurely-paced trip to town for some new pads, springs, adjuster kit, and a drum was made quite memorable by the fact that even the manufacturer doesn't make the cylinder pins anymore (an assumption on my part, due in large to the fact that the local dealership told me that they couldn't be ordered). When I asked them what they do when a vehicle comes in needing those parts, I was told, matter of factly, that "nothing ever happens to those". That's great--thanks for the assurance.

Upon returning to the workshop to put my little fiasco aright, things really got interesting. The brake lines that were supposed to have been replaced not long prior to my purchasing the vehicle were having nothing to do with the whole "free spinning coupler" idea. Add one ruined brake line to the list of replacement parts. It was only after I got the cylinder installed and began putting the assembly together that I realized that the last trained monkey that worked on the truck assembled the entire set backwards! I'm not talking about the usual drum brake screwups like inverted springs; I mean the entire brake drum was assembled back-friggin'-wards.

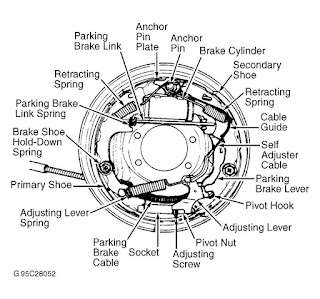

The above diagram is prevalent online. In fact, if you were to contact a dealership to get a diagram of the drum from their records, it is pretty much the same thing, though exploded. This graphic shows the right rear drum. To use this picture to assemble the left rear, you have to invert the image. This is why the retainer pins and cylinder pins were bent and the emergency brake guts were left out--there was a good deal of force required to put it all together in this manner. If you assemble it in the proper direction, everything literally falls into place. This is why the diagram includes the emergency brake cable. The E-brake cable comes from the front of the vehicle. Notwithstanding, the adjusting lever is usually mounted on the trailing side of the drum (this is what I noticed from the beginning. It just didn't register immediately as a goof since I haven't worked on drum brakes since 2002), a dead giveaway should be the positioning of the primary shoe.

Now, I realize most of what I just said is gobbeldygook to anyone who hasn't worked on older brakes before. The main point is, I had every bit of this trouble simply because somebody either got in a hurry and cut corners, or they couldn't properly read directions. I've done these rebuilds before, but wasn't too proud to find a diagram or consult another mechanic for advice. The easiest way to hurt yourself or someone else is to think you know how to do something when you really haven't got a clue. The internet is full of people like that--a fact to which some of my electrician friends can attest. I just spoke to a friend of mine in the trade a little while ago who shared a story about someone on one of his jobs wiring a phase to ground. In non-electrician lingo, that is a good way to get your chicken Kentucky-fried in a hurry.

Though we wish it were, life isn't always simple. Not everything you do can be as mindlessly simple as building birdhouses or changing light bulbs, nor is everyone fully equipped to do everything. If the sum of your electrical experience is plugging appliances into the wall, then you probably shouldn't take on the task of updating your breaker box. Need a brake job but have never done one? Get an experienced person to show you how to do it, rather than muddling through and maybe injuring someone in the process (or aftermath). You've heard the phrase, "you can't fix stupid". It turns out that you can, usually with an inordinate amount of labor and swearing. The thing is, it's much easier to just head it off at the pass. . .

No comments:

Post a Comment